Management Principles

Our Mission

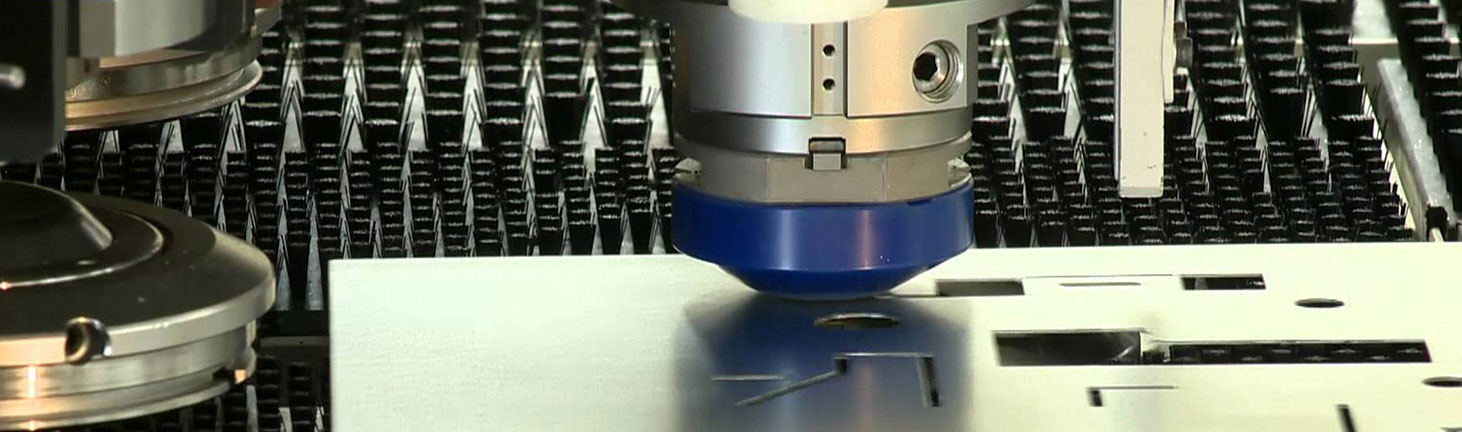

To provide the most cost-effective solutions for CNC Turret Punching Services, Sheet Metal Bending

Services, and Fabrication Services. With a deep commitment to customer service and supply chain

inventory management systems, we are able to provide an immediate response to your most

challenging requirements.

Our Vision

We believe in long term business relationship. Our ultimate aim is to satisfy our clients with our services.

We do not compromise with the quality, genuineness and workmanship which leaves a permanent

impact on our customers and invariability they recommended our services. We want to develop

professionalism in the field.

Our Values

Customers are at the center of everything we do - and that is reflected in our company's vision and

values. While our vision defines our destination, our core values serve as our road map guiding our

actions for the benefit of all of our stakeholders.

Our AIM

We have plans for fast and continued healthy growth in the local and global markets based on our

quality, technology, strong foundation and market reputation.

We can say with pride that we have been delivering our promises to our customers with emphasis on

quality and timely delivery.

We have built a strong market reputation in the fabrication services on the basis of our quality services

and products.

Quality

We at MAHAKAYA Engineering Pvt Ltd believe that quality is not an accident; it requires systematic,

intelligent effort and devotion to accomplish total satisfaction with respect to our customers, and the

latter lies in prompt, timely deliveries of detect-free products & services. This requires continuous

monitoring of products, processes and system, which is very efficiently handled by our qualified team.

This ability is further enhanced by periodic visits of QC personnel to customers to get accurate feedback

on the actual performance.

QUALITY POLICY

We at MAHAKAYA Engineering Pvt Ltd are committed to customer satisfaction in all respect like,

• On time Delivery of zero defect products

• To produce material exactly as per customer’s requirement

In addition, involvement of all the people in the growth of organization and to continually improve the

effectiveness of Quality management system.

QUALITY OBJECTIVE

• To Improve Delivery to Customer

• To Minimize Customer Complains

• To Enhance Customer Satisfaction

• To Increase Customer Base & New Product

MANUFACTURING – JOB WORK AND SOURCING TYPE BUSINESS

We give preference and priority to those jobs where sourcing activity is involved. We have two separate

activities; the first is ‘JOB WORK’, where we get material from the customer; and the second is

‘SOURCING TYPE BUSINESS” where the customer provides the Bill of Material (BOM) along with all

technical specifications and preferred makes. After getting the data we verify the BOM along with the

sample, and then we register the same in our ERP system. Our Purchase Department uses the System

Generated BOM and floats the enquiries to our approved suppliers.

Our goal is to provide the most cost-effective solutions for contract manufacturing. With a deep

commitment to customer service and supply chain inventory management systems, we are able to

provide an immediate response to your most challenging requirements.

Our quality control standards are a priority in serving the needs of our customers because

manufacturing & inspection processes are created to assure quality assembly work. Our adherence to

strict quality control standards and investment in high-tech and high quality production and assembly

equipment have attracted and retained priority customers who have established extremely rigid product

quality standards.

How We Build Quality into Our Products & Services

• Products are designed for reliability. Aside from functionality and performance, reliability is expected

from and built into each new design.

• Purchasing 100% genuine raw material directly from manufacturers and authorised dealers & using the

same for achieving best & reliable solder joints quality.

• Components are sourced from reputed manufacturers/dealers & reputed sources directly.

• Inward inspection of all components is done on a sampling basis.

• 100% inspection of each product both in-process as well as post production.

• Complying with applicable statutory, regulatory & customer requirements.

• Strict control over environment

• All production and quality personnel are periodically trained by senior technical management personnel.

• Encouraging & Cultivating, Competence, Commitment, Honesty, Trust & Sincerity towards our clients.